Solution that visualizes production line quality (OK / NG) in real time and facilitates quality control.

- Product Description

-

ATS Inspect is a solution that visualizes production line quality (OK / NG) in real time and facilitates quality control.

Enables in-process control of defective products. In addition, digital traceability of quality records becomes possible, contributing to the prevention of intentional quality data tampering.What ATS Inspect can do

- Going paperless in inspection at manufacturing site

- Checklist

- Appearance defect inspection

- Building digital traceability

- Prevention of inspection data tampering

- Auto-generation of report for quality improvement

- Quick visualization of defect occurred at the manufacturing site

- Going paperless in inspection at manufacturing site

Product Features

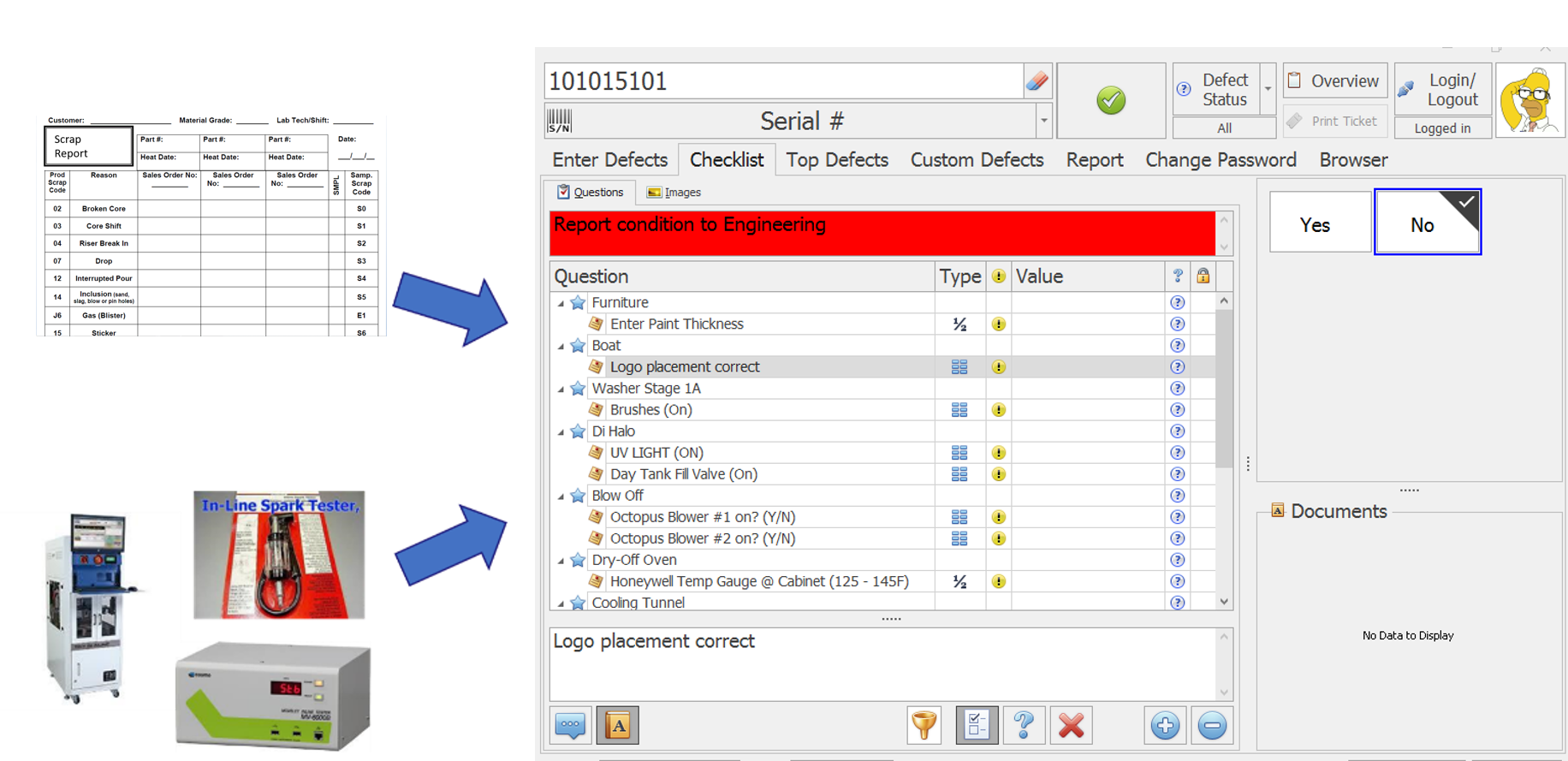

Checklist

Paper-based management of work instructions/inspection instructions will go paperless. The visual check result can be input manually, or the result sent from the equipment is entered automatically.

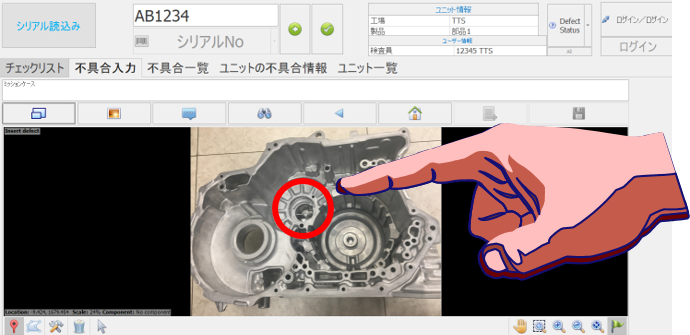

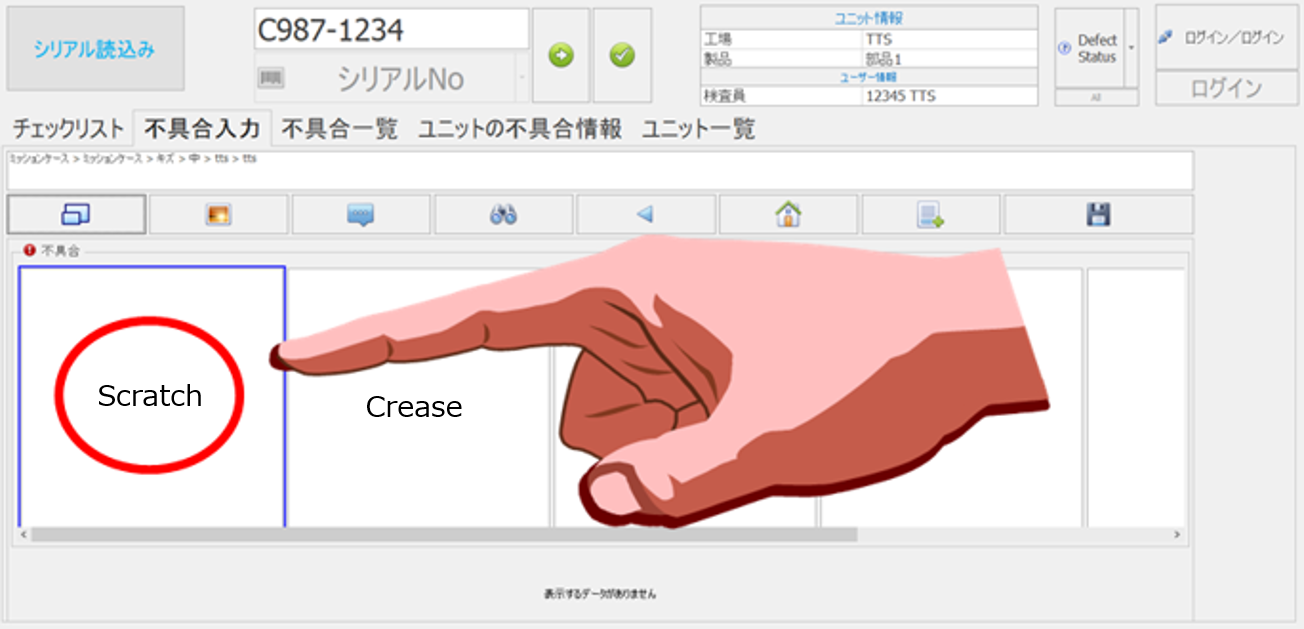

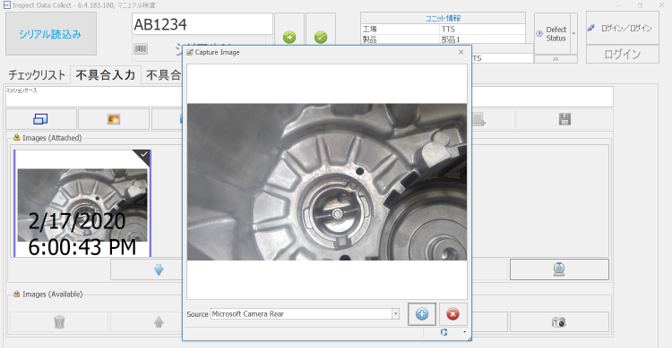

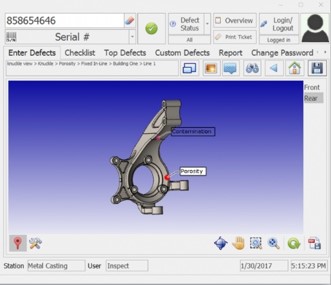

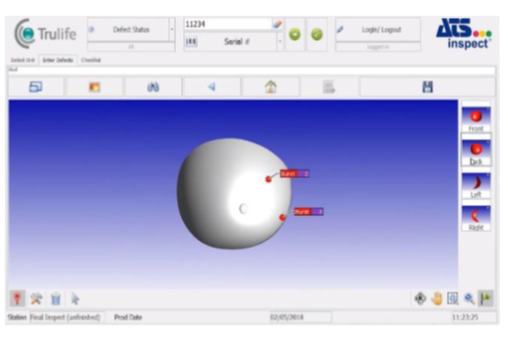

Appearance inspection

The inspection result from visual check or equipment can be paperless input. Since the entered defects have coordinate values, defects are automatically totaled for each part/area in the report.

【Touch the spot of defect】

【Select the defect content】

【Register the defect image with a tablet camera】

【The defect is registered】

【Easy operation on a tablet】

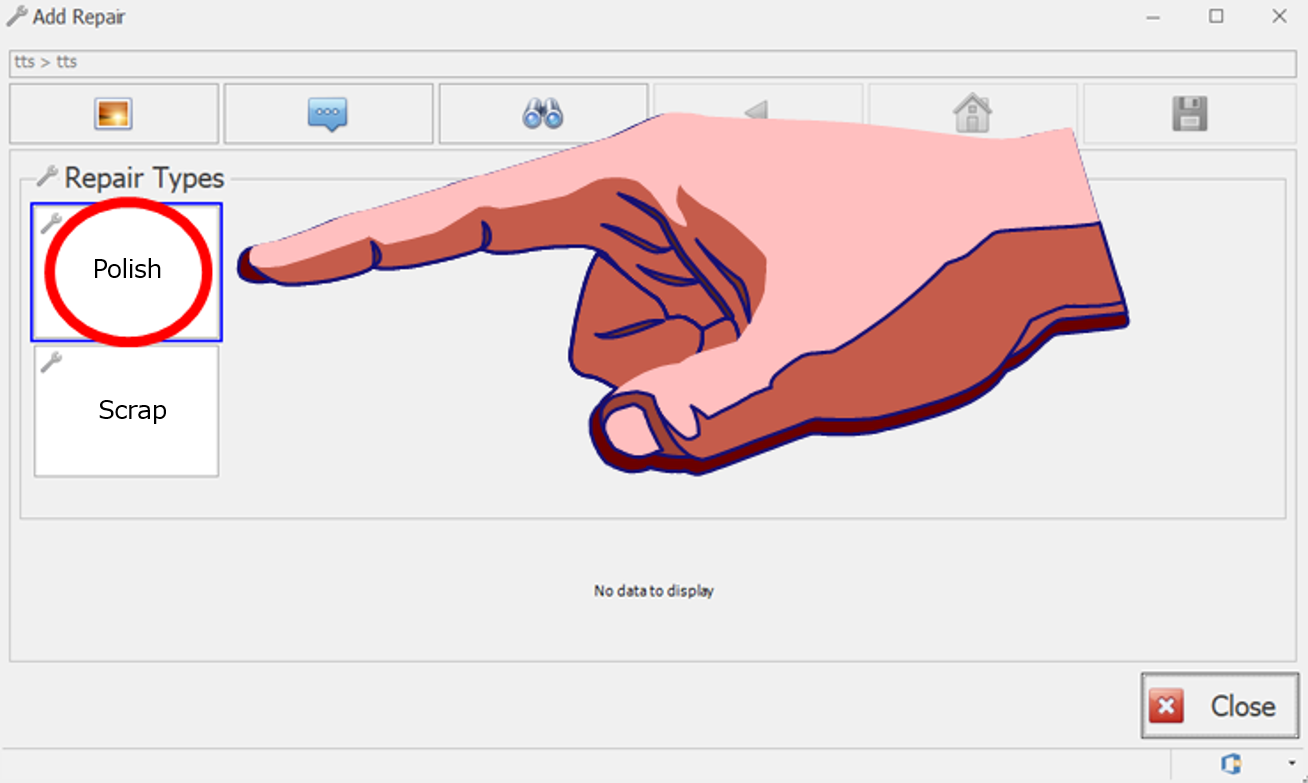

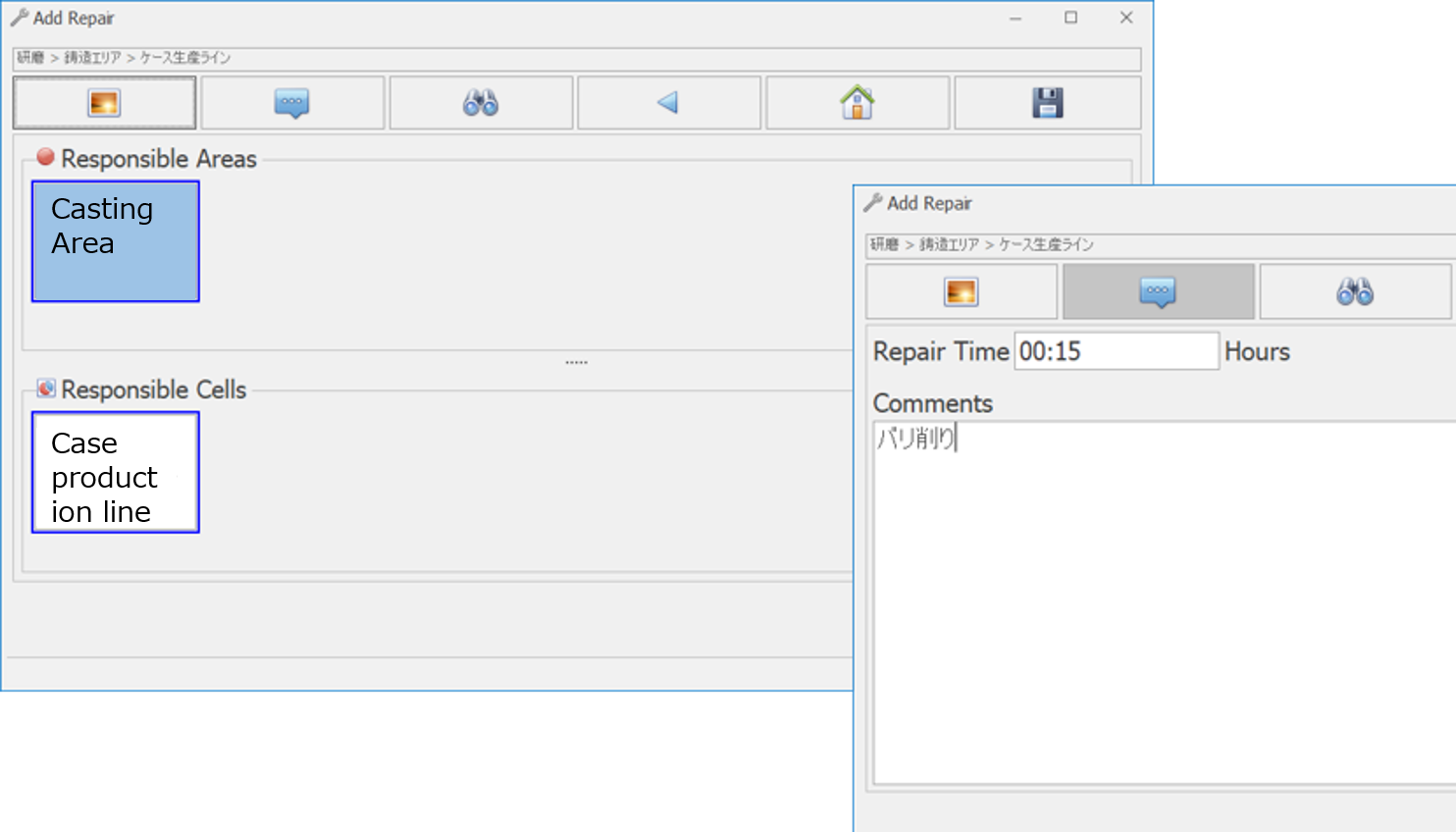

Repair/Approval

For the registered defect, input the repair type, location where the defect occurred, responsible department, repair time to repair the defect. There is an approval function for repaired defects.

【Select the repair type】

【Select the responsible area and responsible cell/ Repair time can be recorded】

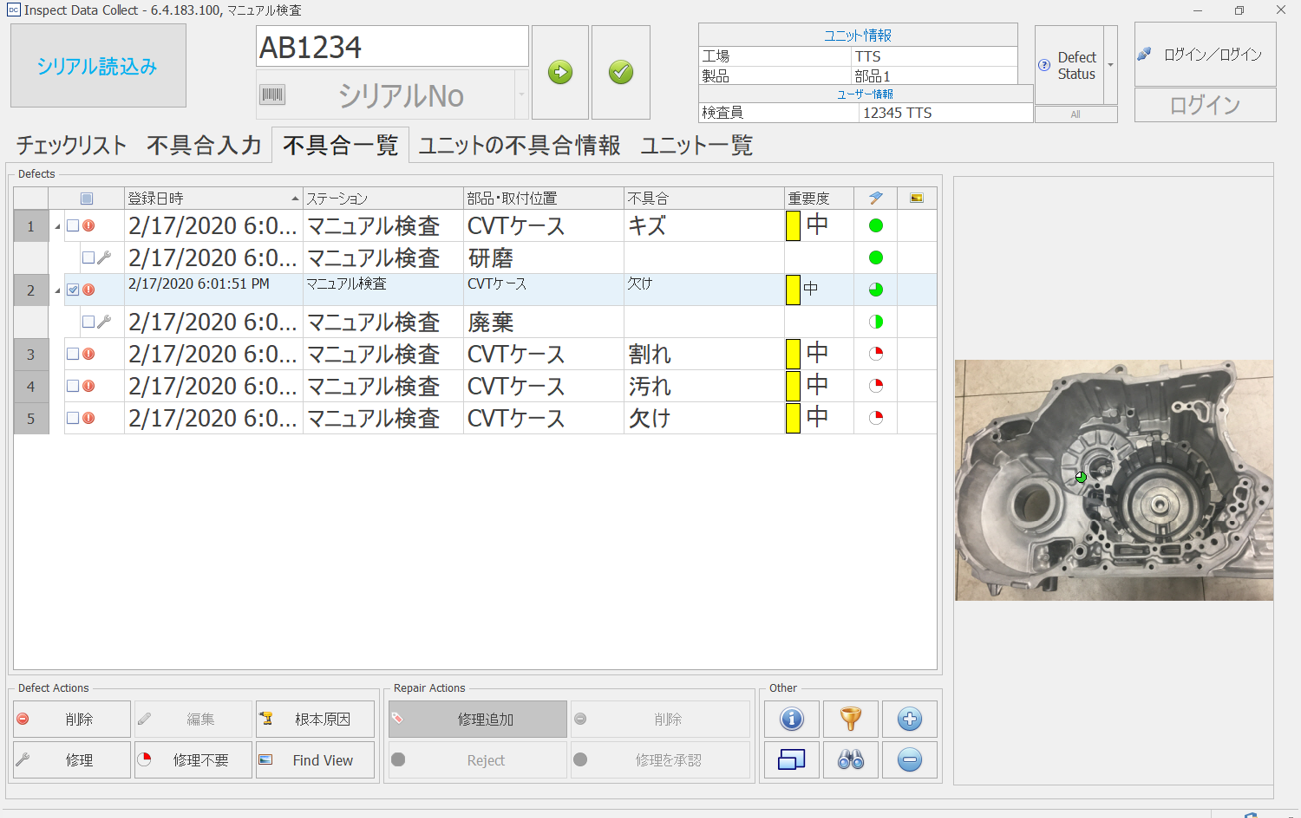

Defect management overview

Status of repair and approval of the defects are managed on the defect management overview after those defects are automatically registered to the overview. It can prevent any defective products from going out to the next process.

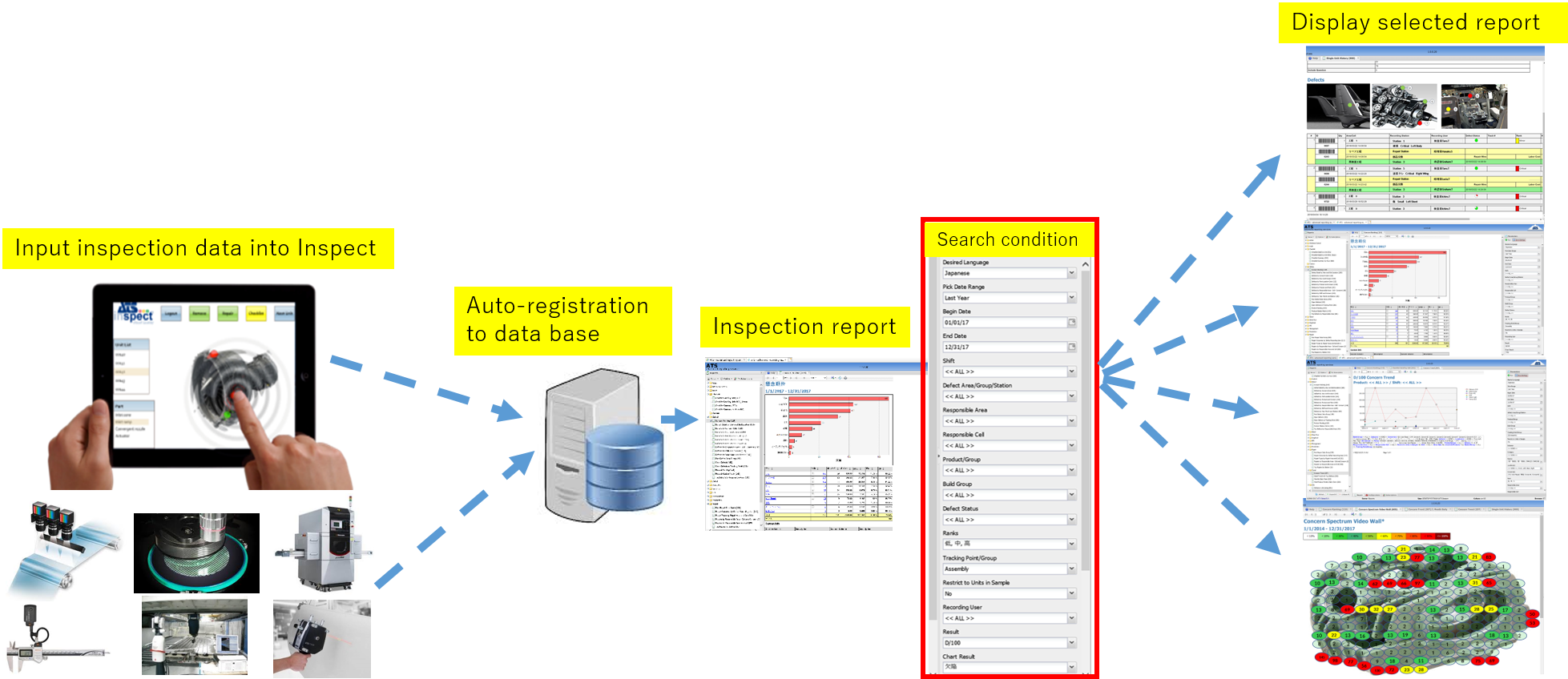

Quality improvement report

Answers to the checklist and entered defect information are automatically output as a quality improvement report with arbitrary filter information. There are about 250 standard templates.

Report generation with no organizing work

- Automatically generates any kinds of report!

- Utilizes fresh data!

- Prevents data tampering by digital traceability!

Related Solution

-

High quality assurance in truck manufacturing

-

Digitization of quality inspection of metal casting products (paperless)

-

Improve product quality and production efficiency of jet engines

-

Improving the quality of white goods (improving appearance defects)

-

Improving product quality and production efficiency at medical device manufacturers