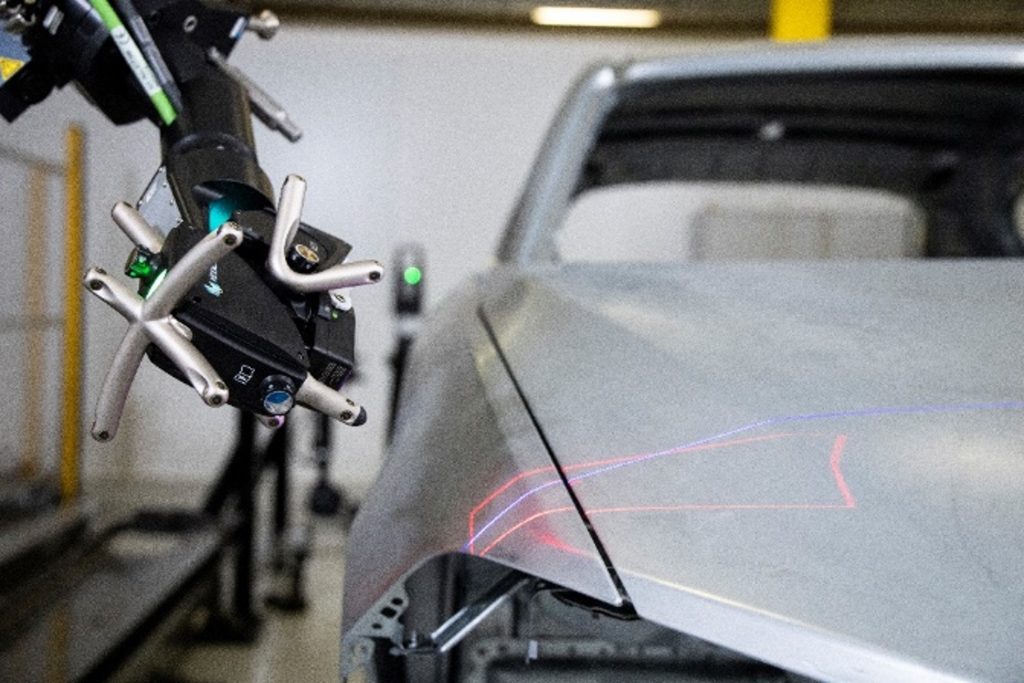

Automate the entire process from measurement to output of result reports by having the robot equipped with a non-contact scanner.

Product Description

- It takes just a few minutes for general automobile press and ASSY and 30-60 minutes even for a white body to measure.

- Resistant to surrounding brightness and temperature variation, and stable measurements are possible over a long period of time.

- Data acquisition rate, measurement accuracy, and measurement time are not dependent on the operator’s skill.

- Not only to automobiles, it can be applied to various applications such as aircrafts and trains.

- In addition to robots, it is also possible to realize automatic measurement by integrating devices such as scanners and probes into machine tools.

Recommended for manual machine users facing the following issues.

Problems in press and body inspection using 3D measuring machines

- Takes many hours for measurement.

- As it is point measurement, it is difficult to find trends other than the inspected points and grasp the cause of the defects.

- A dedicated temperature-controlled inspection room is required.

Problems in press and body inspection using other non-contact scanners

- It is time-consuming to prepare for measurement due to the need for target markers and photogrammetry for alignment.

- Measurement accuracy of holes and edges is not stable.

- Noise due to secondary reflections occurs if no anti-reflection spray is applied to heavily glossy areas.

Product Features

Hardware system configuration

We offer the optimum system according to the object to be measured and the location where the system is to be installed.

The followings are the examples of typical system configurations.

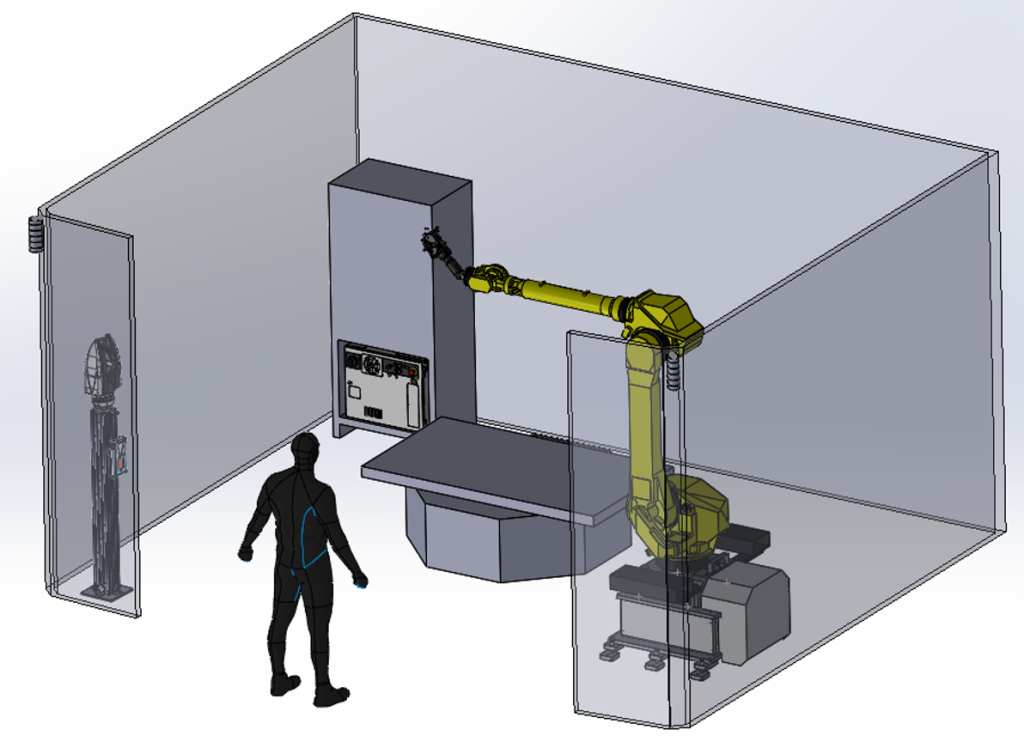

Standard measuring system for press and ASSY

| Equipment dim. | 5000x4100x2700mm3 |

|---|---|

| Max. measurable range | Φ2000mm |

| Max. object weight | 1000kg |

| Axis | 7 axes (6 robot axes + rotary table) |

| Delivery entrance | Light curtain |

| Scanner | AS1, T-Scan5 |

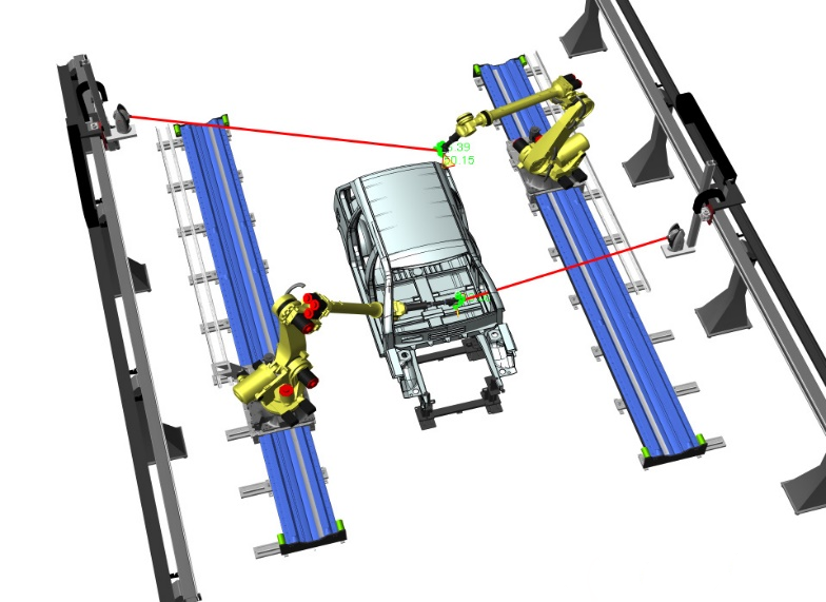

Standard measuring system for white body

| Equipment dim. | 10000x10500x4000mm3 |

|---|---|

| Max. measurable range | 5000mm×2000mm |

| Axis | 7 axes (6 robot axes + traveling axis) x 2 |

| Delivery entrance | Light curtain |

| Scanner | AS1, T-Scan5 |

Offline teaching

- Offline teaching is available with a software dedicatedly developed for the Leica automated measurement system.

- Optimized scan paths can be automatically generated for each element, such as holes and surfaces.

- Route between scan paths is automatically created in a way that avoids interference as well.

- Highly accurate offline simulation considering the positional relationship between the tracker and scanner is possible.